Product Detail

Air Blower Transportation

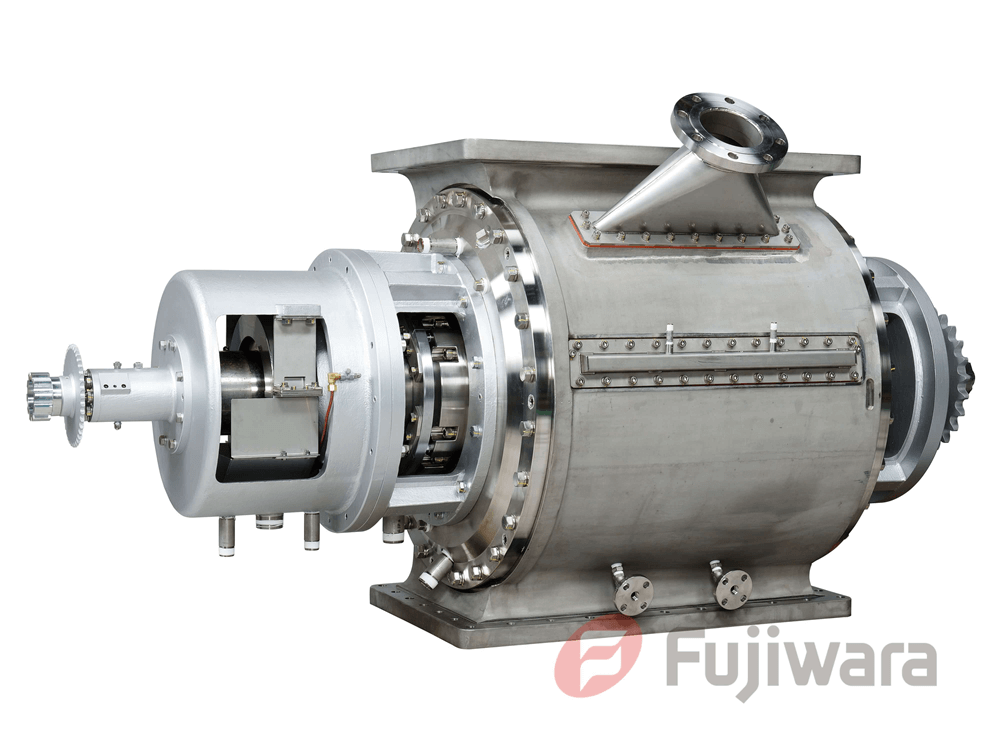

Horizontal type rotary valve Neo RV

Good sealing performance for a long period of time Material transfer with less adhesion

durability

material transfer

design

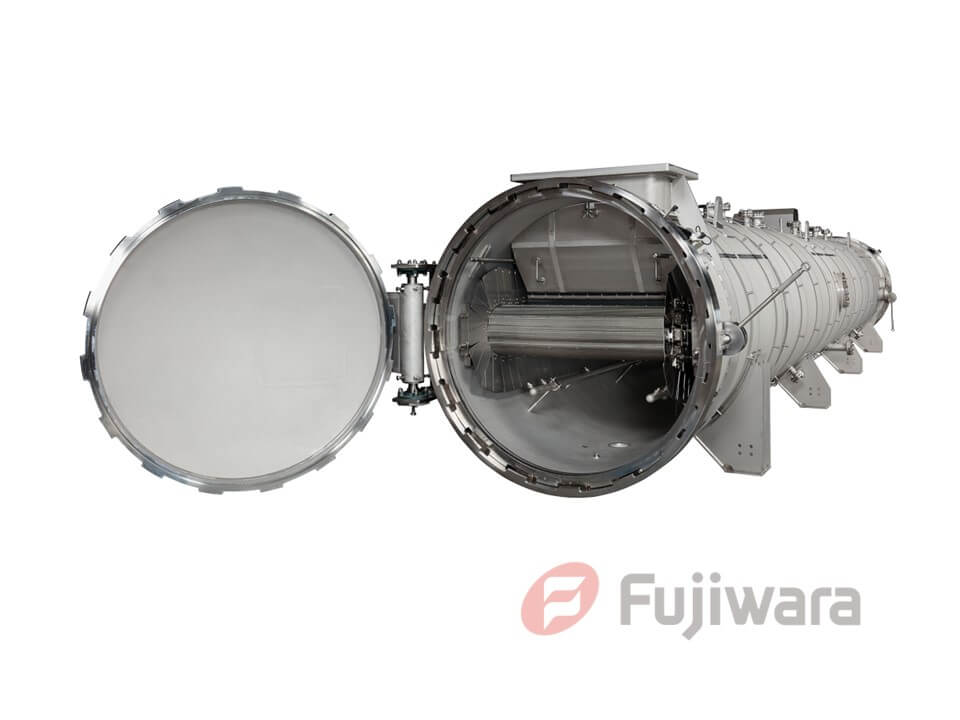

■ Outline

In continuous pressure steaming equipment, this device is used to feed and discharge materials while maintaining pressure.

The parts in contact with raw materials are made of stainless steel and boast high durability. The gap between the casing and rotor is sealed by a non-contacting minute gap, maintaining good sealing performance for a long period of time.

The gap is automatically adjusted to minimize steam leakage. This lowers running costs.

■ Point

1.Non-contact micro-gap seal between rotor and casing maintains excellent sealing performance for an extended period of time.

2.Automatic adjustment method for the micro gap.

3.Water-cooled rotor and mechanism to prevent raw material from adhering ensure smooth and reliable raw material transfer.

4.Very easy to clean after operation.

Related Words

■ Download Documents

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry